Fires can be devastating. It can cause loss of property, data, belongings, equipment, livelihood, and lives. In New Zealand, the second most popular cause of fire incidents is electrical failures brought about by electrical failures caused by substandard or faulty electrical appliances, tools, equipment, devices, and machinery.

What do you mean by test and tag?

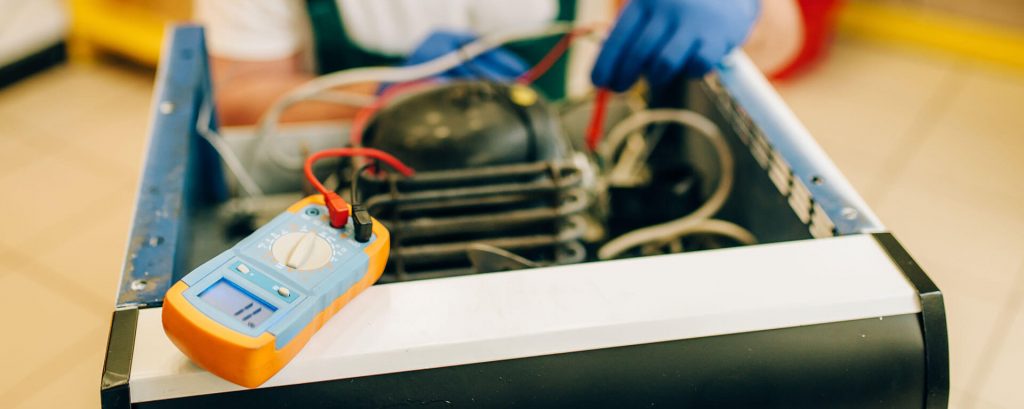

Test and tag is the process of inspecting electrical devices, tools, and appliances as well as its parts to determine their safety. The parts include chargers, power cords, and connecting cables. This process has to be done to determine properly the property’s electrical capacity such as the number of electrical devices to be handled and if the connections tend to overload the circuit. It operates on the fact that every device that must be plugged into an electrical source has to be tested for safety.

When do you test and tag?

Based on the standards and regulations in Whangarei and anywhere in New Zealand, all electrical equipment, tools, devices, and leads sold have to be tested regularly. This is to lower the risk of workers who use them. The process test and tag must be conducted only by trained and skilled professionals using only the appropriate testing tools.

New electrical appliances must be tested before initial use. Some of the appliances that require testing are power boards, residual current devices, battery chargers, portable outlet devices, flexible cords, and others. Those that don’t require testing are appliances that are fixed and wired to the wall, those that require dismantling to be tested, LAN cabling and main outlets, and light fittings that are suspended from the ceiling, and similar appliances that have a low risk for electrocution.

How often must people test and tag?

In Whangarei, New Zealand, the regulation on testing and tagging frequency is under the NZS 3760 Standard. It has recommendations on how often the process has to be done according to the environment. The recommendations are as follows: three months for construction, demolition, and building; six months for factories, warehouse, and production; 12 months for environments where equipment/cord is prone to flexing or abuse such as schools, offices, and office kitchens; and 5 years for environments where it is not like in server rooms.

Test and tag is also necessary after every appliance is repaired or serviced which could affect its electrical safety or if the appliance is reintroduced to service.

The process testing and tagging must only be conducted by trained professionals with appropriate course certification.

Fireco offers test and tag professional services in Whangarei and Auckland. They’re ready to tackle any test and tag requirement you have.